ASTM A106 Carbon Seamless Steel Pipes | Hot-Rolling Tube Manufacturer

- modelo

- ASTM A106

propiedad

- Certification

- API

- Standard

- ASTM A106

- Grade

- Gr.B

- Out Diameter

- 1/2" - 24" ( DN15 - DN600)

- Thickness

- 2.24-59.54mm

- Length

- 6M/ 12M or Customized

- Ends

- Plain/ Bevel/ Threaded/ Grooved

- Usage

- Water transfer pipes/ Oil pipes and Gas pipes

- Surface

- Bare/ Black/ Varnish/ Oiled/ Galvanized/ 3PE, etc

Evaluacion

Descripción

Specification

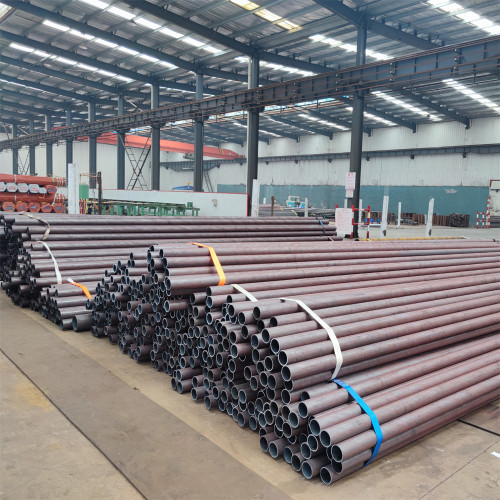

ASTM A106 Gr.B Carbon Seamless Steel Tubes

ASTM A106/ASME SA106 pipe is a carbon steel pipe manufactured by hot rolling. A106 pipe is particularly suitable where the fluid being conveyed is of high temperature or pressure (or both). Astm 106 pipe can be used in high temperature applications (up to 750 degrees Fahrenheit).

It is used not only for piping systems in different industries, such as the transport of oil and gas, water and mineral slurries, but also in boilers, buildings, structures and other applications.

ASTM A106 is generally used in carbon steel, where Grade B pipe is equivalent to ASTM A53 Grade B and API 5L Grade B in terms of chemical position and mechanical properties.

Application for ASTM A106 Tube

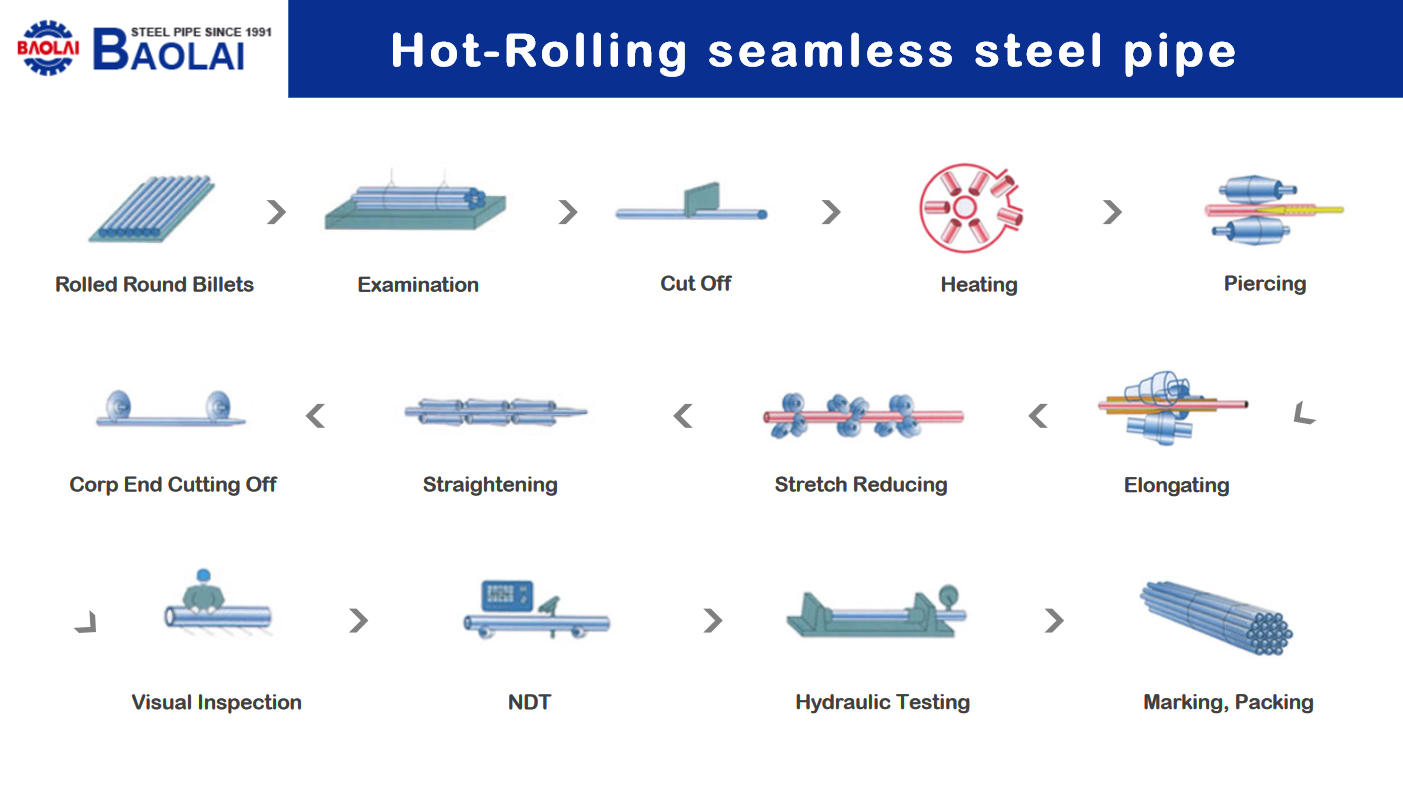

Hot-Rolling Pipe Production Process

Hot-rolled seamless steel tubes are one of the ways in which seamless steel tubes are produced, and are manufactured by the hot-rolling technique, which, as the name suggests, rolls at a high temperature, so that there is little resistance to deformation and large deformations can be achieved.

In contrast to cold rolling, hot-rolled seamless steel tubes are seamless steel tubes rolled above the recrystallisation temperature, whereas cold rolling is done at room temperature. The hot rolling process is usually used on larger diameter seamless steel tubes (above 38 mm). Smaller diameters of seamless steel tubes can be cold rolled or cold drawn.

Example Size

NPS Designator | DN Designator | Outside Diameter | Wall Thickness |

Weight Class

|

Schedule No. | Test Pressure, psi | |

mm |

mm |

Grade A | Grade B | ||||

1/2" | 15 | 21.3 | 2.77 | STD | 40 | 4.8 | 4.8 |

3.73 | XS | 80 | 5.9 | 5.9 | |||

4.78 | - | 160 | 6.2 | 6.2 | |||

7.47 |

XXS

|

- | 6.9 | 6.9 | |||

6" | 150 | 168.3 | 4.78 |

-

|

- | 7.0 | 8.2 |

5.56 | - | - | 8.2 | 9.6 | |||

6.35 | - | - | 9.4 | 10.9 | |||

7.11 | STD | 40 | 10.5 | 13.0 | |||

7.92 | - | - | 11.7 | 13.7 | |||

8.74 | - | - | 12.9 | 15.0 | |||

9.52 | - | - | 14.1 | 16.4 | |||

10.97 | XS | 80 | 16.2 | 18.9 | |||

One-stop service to facilitate your purchase

The Baolai Group continues to provide service and support after your purchase. To save you time, we offer you numerous value-added services such as processing, logistics management and testing.

Processing Services:

- √OEM & ODM

- √Protective Coatings

- √Saw and Flame Cutting

- √Beveling, Threading and Grooving

- For more information, please contact our service team.