API 5L Carbon Seamless Steel Pipes Manufacturer | API Certification

- modelo

- API 5L

propiedad

- Certification

- API

- Grade

- Gr.B/ X42/ X52/ X60/ X65

- Out Diameter

- 1/2" - 48" ( DN15 - DN1200)

- Wall Thickness

- Sch40/ 80/ 120/ 160

- Length

- 6M/12M or Customized

- Ends

- Plain/ Bevel

- Usage

- Oil and Gas/ Water Pipeline

- Surface

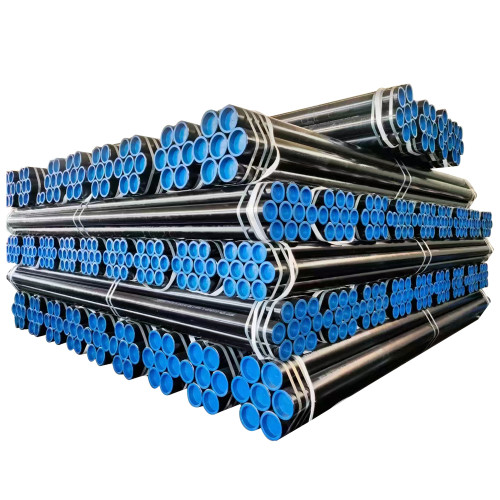

- Bare/ Black/ Varnish/ Oiled/ Galvanized, 3PE, etc

Evaluacion

Descripción

Product Description

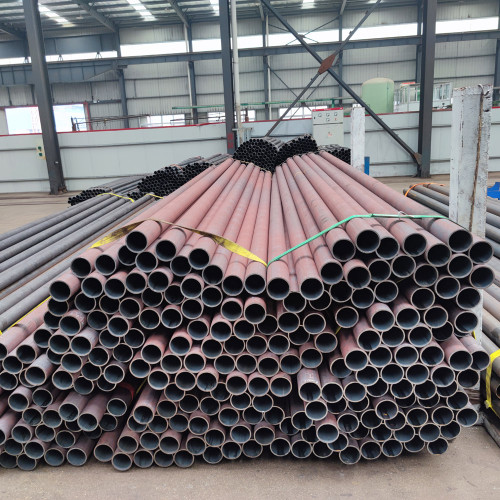

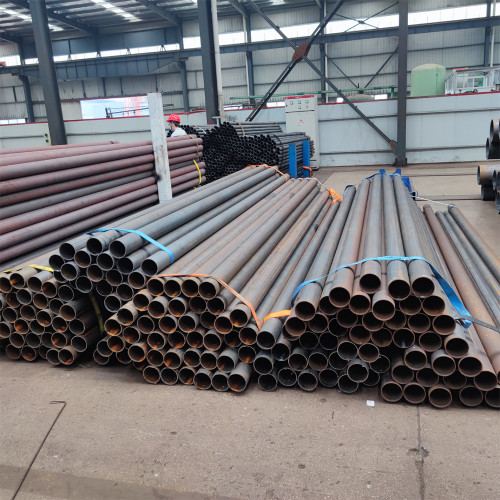

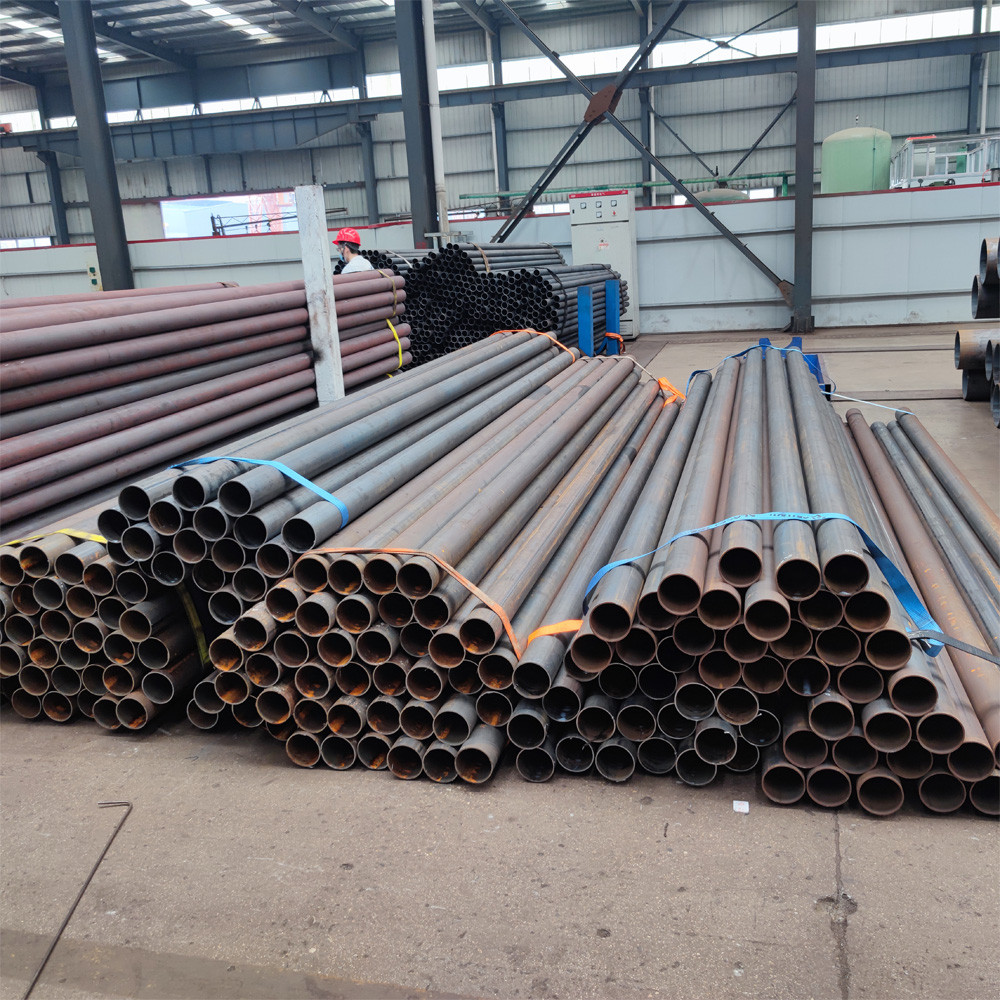

Seamless Steel Pipes/Tubes

Out Diameter: Wall Thickness:

1/2'' (DN 15) - 36'' (DN 600) 1.25mm - 50mm

21.3mm - 610.0mm SCH10,SCH40(STD),SCH60,SCH80,SCH160(XXS)

Seamless carbon steel pipe is made by hot rolling and piercing a solid billet through it to leave a hollow pipe/tube. The pipe is then shaped to size and heat-treated to specification. Seamless steel pipe was applied to the petroleum, power plants, chemical industry, boilers, building materials, and other fields. Seamless steel pipes are high in hardness, strength, wear resistance, and anti-corrosion.

API 5L pipeline is the oil, natural gas, and water transmission pipeline specified by the American Petroleum Institute, including seamless and welded steel pipes.

API 5L line pipes are available in multiple carbon steel grades, designated as Grade B, X42, X46, X52, X56, X60, X70, and X80, and in PSL1 or PSL2 specification levels. The following is the difference between PSL1 and PSL2 and the introduction of common steel grades.

Help cut down on expenses.

Athough more expensive than welded pipe,but this increased ability to withstand pressure allows to use pipes that are thinner and lighter,so the total price is lower.

Differences between PSL1 & PSL2

PSL1 Seamless Pipe | PSL2 Seamless Pipe |

|

CVN impact (Charpy) testing | None required | Required for all grades |

Nondestructive Inspection of Seamless | Only when purchaser specifies SR4 | SR4 mandatory |

Certification | Certificates when specified per SR15 | Certificates (SR 15.1) mandatory |

Traceability | Traceable only until all tests are passed, unless SR15 is specified | Traceable after completion of tests (SR 15.2) mandatory |

Hydrostatic Test | Required | Required |

Application of API 5L Seamless Tube Common Grades

API 5L Gr.B

Gr.B is the most used steel grade in API 5L, which is used for for low pressure fluid lines and serving different mediums, such as the transmission of oil, natural gas, or water.

API 5L X60/X65

API 5L X60/X65 pipeline are also common grade mostly used in the petroleum and oil and gas industries.

API 5L X42

API 5L X42 line pipe is most commonly used in the petroleum industry to transport oil and gas.

Onshore, for transporting oil and gas from wellheads to refineries, and offshore, for transporting oil and gas from platforms to onshore terminals.

API 5L X42 line pipe is also used in other industries such as chemical industry, for chemical transportation, construction industry, for pipeline construction.

API 5L X52

X52 and X42 have the same purpose, but the impact test of - 20 ° is added to X42.

So it is a higher strength steel grade than X42 and is typically used in higher-pressure applications.

At present, the demand for API 5L X52 steel pipes in African countries is increasing.

Example Size

NPS Designator | DN Designator | Outside Diameter | Wall Thickness |

Weight Class

|

Schedule No. | Test Pressure, psi | |

mm |

mm |

Grade A | Grade B | ||||

1/2" | 15 | 21.3 | 2.77 | STD | 40 | 4.8 | 4.8 |

3.73 | XS | 80 | 5.9 | 5.9 | |||

4.78 | - | 160 | 6.2 | 6.2 | |||

7.47 |

XXS

|

- | 6.9 | 6.9 | |||

6" | 150 | 168.3 | 4.78 |

-

|

- | 7.0 | 8.2 |

5.56 | - | - | 8.2 | 9.6 | |||

6.35 | - | - | 9.4 | 10.9 | |||

7.11 | STD | 40 | 10.5 | 13.0 | |||

7.92 | - | - | 11.7 | 13.7 | |||

8.74 | - | - | 12.9 | 15.0 | |||

9.52 | - | - | 14.1 | 16.4 | |||

10.97 | XS | 80 | 16.2 | 18.9 | |||

One-stop service to facilitate your purchase

The Baolai Group continues to provide service and support after your purchase. To save you time, we offer you numerous value-added services such as processing, logistics management and testing.

Processing Services:

- √OEM & ODM

- √Protective Coatings

- √Saw and Flame Cutting

- √Beveling, Threading, and Grooving

- For more information, please click here or contact our service team.